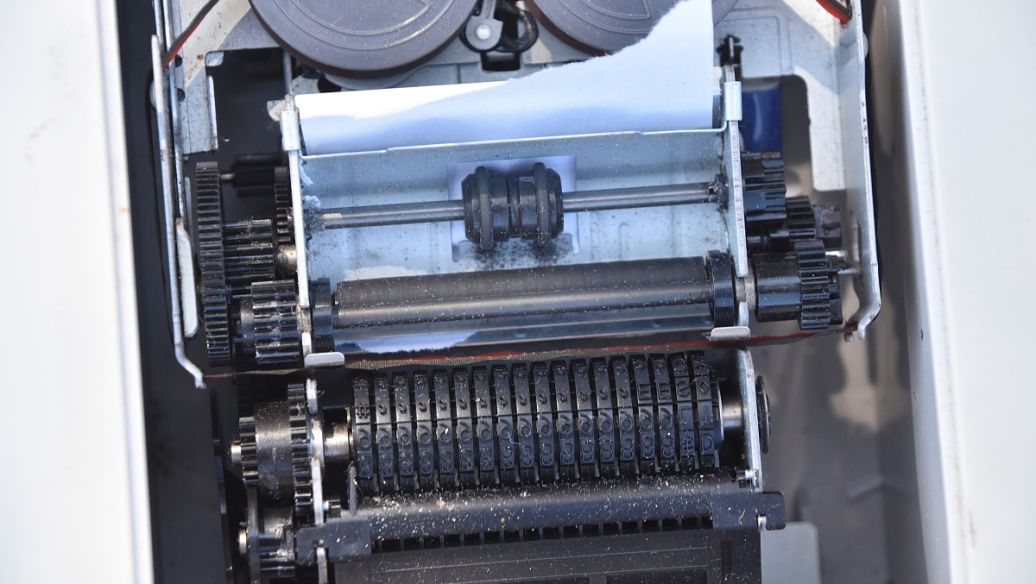

Add oil to the main slide block and other transmission parts 2 to 4 times a day.

Grease should be added to the bearing to ensure lubrication, so as not to burn the bearing. Pay attention to the maintenance, repair and abnormal handling of the bearing at any time.

In order to maintain the original performance of the bearing in a good condition for as long as possible, maintenance and repair are necessary to prevent accidents before they occur, ensure the reliability of operation, and improve productivity and economy.

Maintenance should be carried out regularly in accordance with the operating standards of the mechanical operating conditions. The content includes monitoring the operating status, replenishing or replacing lubricants, and regular disassembly inspections.

As maintenance items during operation, there are bearing rotating noise, vibration, temperature, lubricant state, etc.

Proper lubrication and maintenance can maximize the bearing life.

Grease lubrication

The relubrication of the bearing is best implemented during the planned equipment shutdown period and regularly replenished. At the same time, the old grease is removed or the old grease is squeezed out through the oil drain. The grease nozzle should be wiped clean before adding fresh grease. If the bearing box does not have a grease nozzle, the bearing box cover or end cover should be opened to take out the old grease. After cleaning, add fresh grease of the same model.

Lubricating oil

Regularly check the oil level and quality of the lubricating oil. Normally, the normal oil level should be 1/3 of the equipment oil level window or mark

-2/3 range. The oil replenishment method is an oil cup, and the displayed oil level only represents the oil replenishment capacity, and the oil level of the bearing box meets the operating requirements, and the oil level in the oil cup is less than 1/4 of its total volume.

Inspection and replenishment methods, take out a small amount of lubricating oil as a sample and compare it with fresh lubricating oil. Capable units may consider conducting an oil quality test to ensure that the oil quality is qualified. If the sample looks like a cloud, it may be the result of mixing with water, that is, the oil emulsification often referred to, and the lubricant should be replaced at this time. If the sample path becomes dark or thick, it may indicate that the lubricating oil has begun to carbonize, and the old lubricating oil should be completely replaced. If possible, flush the oil circuit with fresh lubricant. When replacing the lubricating oil, make sure that the new and old models of the lubricating oil to be replaced are the same, and add the required oil level.

Use an oil bath lubrication system. If the oil temperature is below 60° (140°F) and the lubricating oil is not contaminated, the lubricating oil can be replaced once a year. If the oil temperature is 60-100° (140-210°F), the lubricant needs to be changed four times a year. If the oil temperature is 100-120° (210-250°F), the lubricant needs to be replaced once a year. If the oil temperature is above 120° (250°F), the lubricant needs to be changed once a week.

Correct installation and maintenance are important factors for the normal operation of the bearing. At the same time, care must be taken to maintain the cleanliness of the bearing.

Bearings must be protected from contamination and moisture contamination, and must be properly installed and lubricated. In addition, the design of the bearing arrangement, the condition of the oil seal, the form of the lubricant and the replacement cycle and special maintenance also play an important role and must be paid attention to.

When the machine has abnormal noises and other bad conditions, it should be shut down for maintenance and inspection in time, and it should not work with illness, so as not to affect the service life of the machine.

When the machine parts are damaged, they should be replaced in time to ensure the machine performance and product pass rate.

Safety items for operating the button machine:

The machine has been debugged, the surrounding environment should be cleaned, and no debris can collide with the machine.

After lubricating oil, irrelevant personnel should leave the scene and start work.

When the machine is running, the operator should also leave the running part of the machine to ensure safety.

During the production process, if you want to check the quality of the product, the quality inspector should keep a certain distance from the moving part of the machine and the forming part of the product, and cannot take the product in the dangerous area or do some dangerous actions.